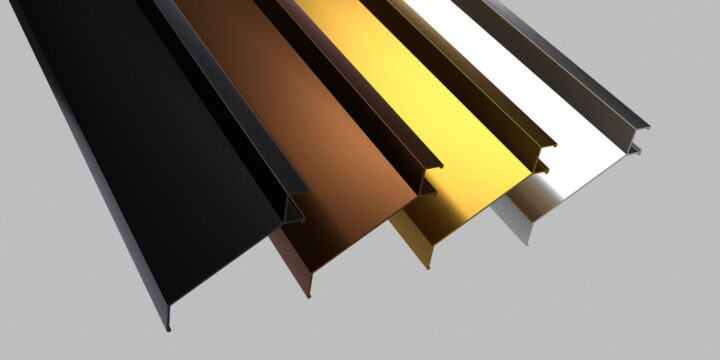

Surface treatment adds character to the facade

Surface treatment is the key to a unique and durable facade. Purso’s anodizing and powder coating provide aluminium with a stunning appearance and strong protection against weather and wear – without compromises.

Anodizing – the art of protecting aluminium

Anodizing is a unique surface treatment method that enhances aluminium’s natural oxide layer.

With anodizing, aluminium surfaces can achieve various shades and gloss levels – the colour palette ranges from subtle metallic tones to deeper, more vibrant colours. This allows architects and designers to create unique solutions that stand the test of time, both in aesthetics and functionality.

The colours offered by Purso add depth and sophistication to surfaces – choose natural silver, electrolytic colour-anodized shades of brown and black, or elegant gold tones.

This treatment makes aluminium harder and even more resistant to corrosion and UV radiation. The anodized surface is exceptionally long-lasting, retaining its colour and appearance even in the most demanding weather conditions.

Colour and durability with powder coating

In powder coating, a fine powder is applied to the aluminium surface and then heated, creating a durable and uniform painted finish.

Powder coating offers almost limitless possibilities in terms of colours and finishes. This allows architects and designers to achieve exactly the look they envision for their projects – whether it’s subtly elegant or boldly vibrant.

You can freely choose the colour shade and gloss level according to your preferences. At Purso’s in-house powder coating facility, various textured and pearlescent effects can also be created.

Powder coating combines style and durability – making aluminium resistant to weather and impact. The powder-coated surface is maintenance-free and long-lasting, making it a practical choice for exterior building applications.

Distinctive style through surface treatment

Contact us!

Contact our sales team directly or send message via form. We will contact you as soon as possible!