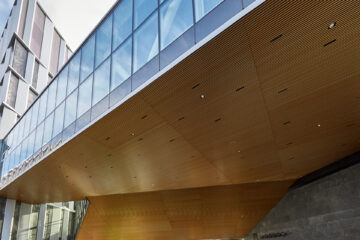

The facade of Nokia Arena shines in shades of silver and bronze

The city of Tampere received a new world-class landmark with the completion of Nokia Arena at the city center. Purso supplied more than 100 tons of aluminum for the façade of the multipurpose arena. The striking slatted profiles stand out from the urban landscape with their exceptional elegance.

– It was a pleasure and an honor to be involved in this wonderful project. The designer of the arena was American architect Daniel Libeskind, who has designed, for example, the Jewish Museum in Berlin. We were honored with the task of realizing his vision as a Finnish operator, says Tommi Kahiluoto, Business Director of Building Systems at Purso.

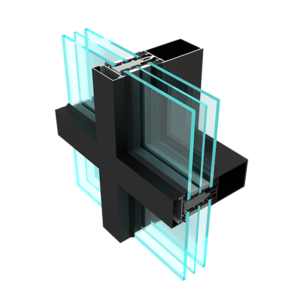

The façade required an equally functional, economical, and impressive solution for the facade. The main contractor SRV ordered the facade contract from Haka pks Oy, a long-time partner of Purso. Purso supplied Haka pks with a customized facade system with fastening materials. The Nokia Arena also utilizes Purso’s structural glazing system as well as lightning elements and handrails.

Aluminum comes in many forms

Purso’s advantage in this demanding project were their own product development, design, and production departments. Extruded aluminum slats manufactured in Finland using advanced production methods are also a responsible choice in terms of logistics, as the distance from Siuro to Tampere is only about twenty kilometers.

– Our design department was strongly involved from the very beginning. We made prototypes of the structures to make sure that the colors and shapes look the way they wanted. Aluminum is a great material because it can be bent into many imaginative forms at a surprisingly low additional cost, says Lauri Hautanen, Purso’s Key Account Manager.

The high quality and requirement levels of the facade made the project challenging. An attractive and vibrant facade must withstand time, usage, and weather. The delivered quantities were also huge – if the slat profiles of the Nokia Arena’s facade were placed in a line, they would amount to more than 30 kilometers.

– A natural, thin, and very durable oxide layer was created for the slat profiles’ aluminum surface finish via adonization. Colored pigment was added to the process for the bronze-hued parts. The unpainted aluminum features a technical and living surface that is wonderfully emphasized in an urban environment, Hautanen says.

– We delivered products during a period of six months, and the bulk of deliveries happened in the first three months. Purso’s basic process is in good condition, and we can meet our promised delivery times. In such a large-scale project, communication with the customer is of key importance, and the varying situations at the construction site require a quick response time. We are very proud of the result, says Kahiluoto.